Trevi’s BEtOfilter

Principle

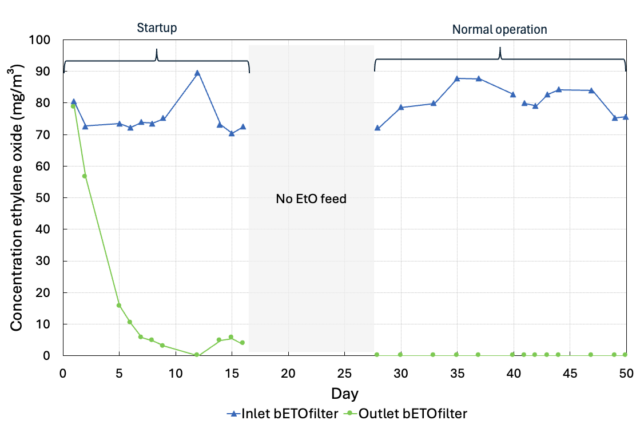

A humidified waste gas is blown through a reactor which is filled with an organic carrier material. On the surface of this carrier, a microbial community is growing, degrading the organic compounds in the waste gas and converting the EtO into CO₂, H₂O and new biomass. The BEtOfilter operates at ambient temperature, without the need for chemicals or natural gas.

Application

- Waste gases with low EtO concentrations, up to 200 ppmv.

- Waste gases with very high gas flow, e.g. aeration room air flows (up to 50,000 cfm).

Key Benefits

Flexible / Robust

- Ideal for room air vents or aeration room vents

- Operates at ambient temperature

- Tolerant of high gas flows (>50,000 cfm)

Efficient / Reliable

- Suitable for low EtO concentrations

- Low-maintenance

- Fully automated

- Very low operating costs

Safety

- Eco-friendly waste gas abatement technique

- No need for chemicals or natural gas

- Production of harmless by-products (water and CO₂)

Speak to an expert

Fill in the form and one of Trevi’s specialists will contact you to discuss your specific EtO removal needs.